Industrial Coffee Grinder for Bulk Coffee Production: Important Details

Industrial Coffee Grinder for Bulk Coffee Production: Important Details

Blog Article

Industrial Coffee Grinder Guide: Boost Efficiency and Quality

In the competitive landscape of coffee manufacturing, picking the right industrial coffee grinder plays a pivotal duty in improving both efficiency and item top quality. Comprehending the subtleties of different mill types and vital features-- such as personalized work settings and robust building and construction-- can significantly affect the final taste profile of the coffee.

Comprehending Mill Types

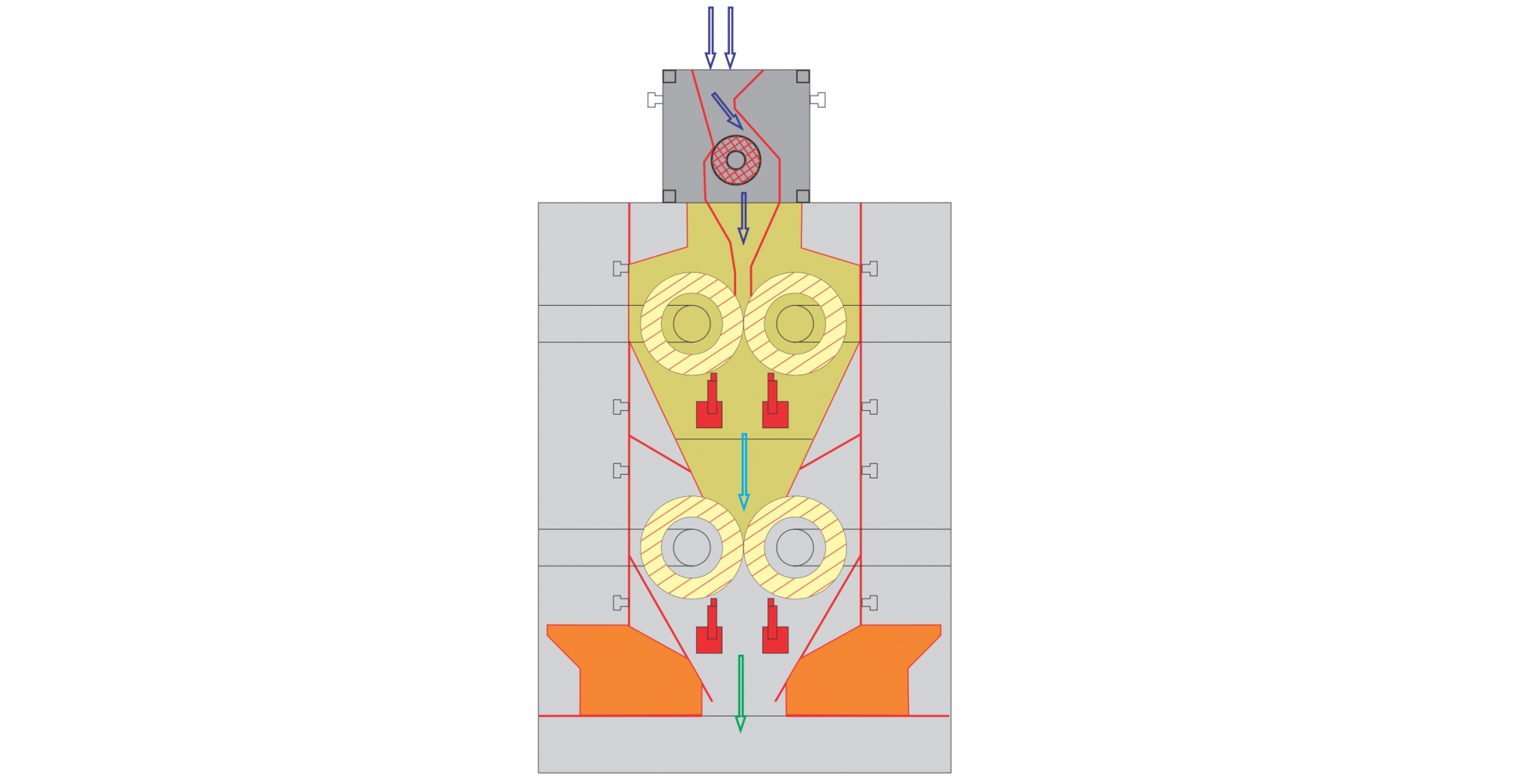

When picking a commercial coffee mill, recognizing the numerous types available is crucial for maximizing both taste removal and functional effectiveness. The 2 main kinds of mills are blade mills and burr grinders.

Ultimately, picking the best kind of mill is integral to maintaining top quality and efficiency in coffee manufacturing, making it vital for companies to buy high-quality burr grinders for optimum results.

Trick Functions to Take Into Consideration

Choosing a commercial coffee mill needs mindful consideration of several vital functions that can considerably influence both efficiency and the overall coffee experience. One of the main facets to examine is the grinding system. Burr mills are normally liked over blade mills, as they offer a consistent work dimension, which is essential for optimum removal and taste.

One more essential function is the mill's ability. A functional mill with several setups permits you to tailor the grind size to different developing techniques, boosting the coffee's flavor account.

The building and construction material also contributes in toughness and maintenance. Stainless-steel components usually offer long life and are much easier to cleanse, which is necessary for maintaining hygiene requirements. Finally, evaluate the mill's noise level, especially in a busy coffee shop or manufacturing atmosphere, where too much sound can be turbulent. Purchasing a grinder that balances these functions can substantially improve both operational effectiveness and the top quality of the coffee served.

Optimizing Grinding Process

To accomplish the ideal outcomes in coffee prep work, enhancing the grinding process is vital. The work size significantly affects extraction, taste, and general top quality of the made coffee.

Additionally, monitoring the grinding rate can optimize the procedure. Slower grinding typically produces less warm, maintaining delicate flavors and aromas. Alternatively, much faster grinding may generate extreme warmth, negatively influencing the coffee's high quality.

Upkeep and Treatment Tips

Correct upkeep and care of industrial coffee grinders are necessary for making certain optimum performance and durability. Regular cleaning is the structure of upkeep; residue accumulation can affect taste and grinding efficiency. It is a good idea to visit here cleanse the mill after each use, cleaning down the outside and removing any type of coffee grounds from the burrs.

Furthermore, examine the grinding burrs for damage. Dull burrs can compromise grind uniformity, so they ought to be replaced as needed. Industrial Coffee Grinder. Occasionally calibrating the mill is also important, as this preserves the wanted grind dimension for numerous developing approaches

Lubrication of relocating parts should be done according to the supplier's specs, as this lowers rubbing and lengthens the life of the equipment. It is necessary to use food-grade lubricants to guarantee safety and conformity with wellness policies.

Finally, maintain the grinder in a stable and completely dry environment to avoid corrosion and rust. By adhering to these upkeep and care suggestions, operators can boost the effectiveness of their commercial coffee grinders while making certain premium result and extended operational life.

Return on Investment Analysis

Reviewing the roi (ROI) for commercial coffee grinders is essential for businesses looking for to maximize their coffee production capabilities. An extensive ROI analysis assists determine the monetary stability of buying top notch mills, permitting services to evaluate the first prices against potential gains.

To conduct an extensive ROI analysis, services ought to consider a number of crucial factors. First, analyze the acquisition rate of the mill, consisting of setup and any required adjustments to existing infrastructure. Next off, determine functional prices, including power usage, upkeep expenditures, and labor efficiency enhancements. High-performance grinders often bring about reduced grinding time and increased throughput, which can dramatically improve productivity.

Furthermore, consider the effect on product top quality. Industrial Coffee Grinder. Superior grinders yield a more consistent work size, which can boost flavor profiles and consumer contentment, eventually see here now driving sales. By raising the high quality of the last product, companies can warrant greater rates, bring about increased profits

Final Thought

In summary, a commercial coffee grinder plays an essential function in boosting both performance and item quality within coffee production. By picking high-grade burr mills outfitted with vital functions such as flexible work setups and long lasting construction, visit this web-site companies can make certain optimum taste removal. Regular upkeep is critical for sustaining mill efficiency and making best use of customer fulfillment. Inevitably, the strategic investment in a trustworthy mill adds considerably to boosted earnings and competitiveness in the coffee sector.

In the affordable landscape of coffee production, selecting the right industrial coffee grinder plays a crucial duty in improving both efficiency and item top quality. The 2 primary kinds of grinders are blade mills and burr mills. Within the burr grinder classification, there are level burr mills and cone-shaped burr mills, each with its advantages. Burr mills are normally favored over blade grinders, as they provide a regular work size, which is vital for optimum removal and flavor.

In summary, an industrial coffee mill plays a crucial duty in boosting both effectiveness and product top quality within coffee production.

Report this page